If you’ve ever purchased artisan cheeses or specialty foods, you’re probably familiar with the brand of imported delicacies Seacrest Foods. This company specializes in importing fine foods and specialty items to the USA. So, whether you’re looking for a perfectly aged sharp cheddar or a sample of exotically flavored meats, Seacrest Foods strives to make those delicious treats accessible to you.

When N.E.T.R., Inc., got the call from the manager of the Seacrest Foods warehouse in Lynn, MA, we were excited for the opportunity to help this company fix its heating and cooling problems. The warehouse air conditioning system was over 40-years-old and beginning to show signs of its age. In addition, the workers had noted that temperatures were fluctuating more than they should.

Because the company deals in perishable foods, the warehouse must be kept at a consistent temperature to ensure the food is safe to consume. Luckily, the faulty cooling system was caught early on, and N.E.T.R., Inc., managed to get on-site and make a diagnosis before the cooling system as a whole failed.

Learn how we helped get the warehouse upgraded to a cooling system that will continue to keep the products cool for years to come.

The Problem: Seacrest Foods’ warehouse in Lynn, MA, had a 40-year-old cooling system in need of repairs.

The Solution: N.E.T.R., Inc., removed the faulty cooling system and installed a new Bohn 52 HP cooling system to help maintain a steady temperature in the warehouse and keep the products adequately cooled.

Removing the Old System

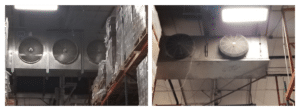

This project manager was Mike Cappuccio, the founder of N.E.T.R., Inc.,. Mike and his team inspected the existing cooling system and found that the evaporator coils were completely worn out. The damaged system constantly needed repairs and couldn’t keep up with the cooling needs of the warehouse.

Before the new equipment could be installed, the old system had to be removed. The team started by removing the R-22 refrigerant from the entire system. This refrigerant was placed into holding tanks and left on-site for the customer to reuse on the remaining older equipment on site after the installation.

Next, the two existing evaporator coils were almost entirely worn out, so they had to be removed. Then, the 40-year-old 40HP system also had to be removed and disposed of according to EPA standards. Because of N.E.T.R., Inc.,’s extensive experience with air conditioning systems, the team was easily able to handle the disposal of this equipment.

All refrigerant piping and evaporator coils on the cooler had to be removed and disposed of properly. Finally, with all of the electrical wiring, piping, and coils unhooked from the system, the new equipment was ready to move in.

Installing the New Equipment

When the outdoor condenser unit was installed, the customer opted for a number of factory options to make the unit fit their needs. The new unit was installed behind the building, where the old condenser unit had been. It featured upgrades like a mounted suction accumulator tank assay and oil separators for both circuits. Additionally, the dual parallel piping option was one of these upgrades.

Inside the cooler, two new MD# BHA1900D 460 VOLTS 3 evaporator coils were installed where the old coils had been. Additionally, N.E.T.R., Inc., installed further steel reinforcements wherever needed. Finally, the new roof supports were installed to help the roof joists hold the additional weight of the larger evaporator coils.

Next, the team installed new refrigerant suction line piping from the outdoor condenser to the new evaporator coils. The suction line refrigerant pipes were 2 5/8 ACR hard pipes that ran from the outdoor unit to each of the new coils in the cooler. Afterward, a liquid refrigerant line piping was installed. These pipes were 1 1/8 ACR hard pipes to carry the refrigerant from the outdoor unit to the coils. All of these pipes required new pipe hangers to be installed for the entire length of the system.

The installation of these parts of the new cooling system required a crane, so N.E.T.R., Inc., brought in a crane to lift the evaporator coils and piping into place. N.E.T.R., Inc., installed all new high-voltage electrical hookups for all equipment, new filters, and all new refrigerant for the system.

After the Installation

Now, Seacrest Foods will have complete control over the temperature of their products while they are in storage waiting to be shipped. This new system is highly sensitive and easy to adjust so that everything will stay at the perfect temperature all year long.

How Can N.E.T.R., Inc., Help You?

N.E.T.R., Inc., is built on a team of high-experienced heating and cooling systems experts who make sure that you always find the solution you need. In addition, we have years of experience helping businesses and homeowners throughout Boston and the surrounding areas find solutions that are customized to their needs.

If you are looking for a commercial refrigeration system that will keep your products cool throughout the hottest days of summer, we can help! Learn more about other commercial installations we’ve done for customers just like you by reading some of our case studies.

Additionally, if you are looking for a heating and cooling solution for your home or office, we can help! Call today to schedule a consultation with our team!